SCADA

Visualisation, control and optimisation of complex systems in real time.

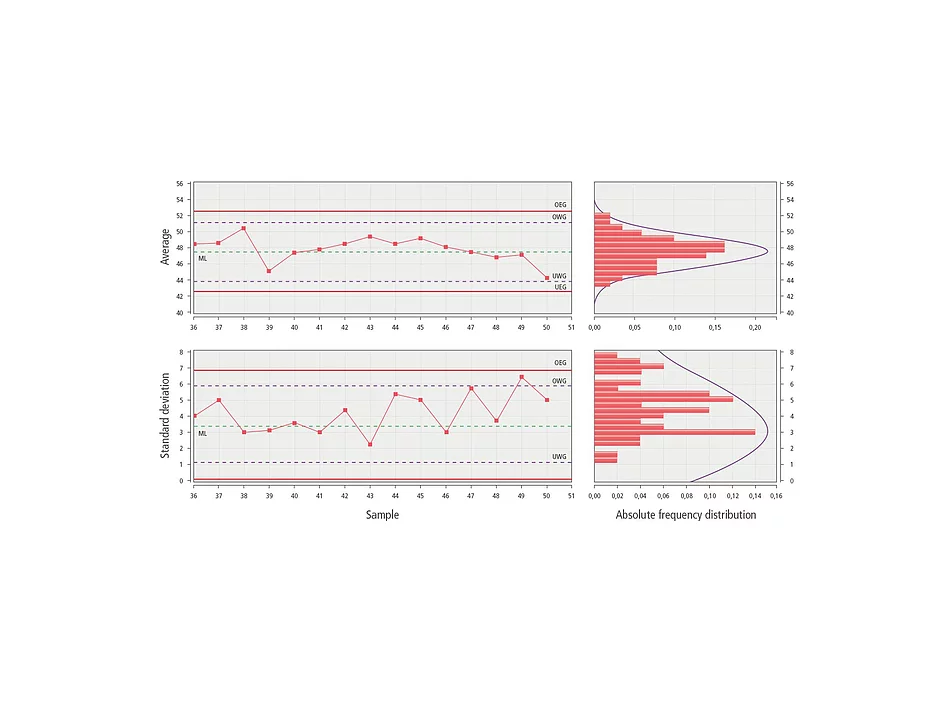

Digital applications that support production processes, which are also driven by the requirements of Industry 4.0, are increasingly playing a central role as planning and controlling entities. celano’s SCADA (Supervisory Control and Data Acquisition) systems provide a wide range of solutions and are used within a wide range of applications.

SCADA / MES

System applications